Industrial traceability reinvented

Learn more about potential use cases

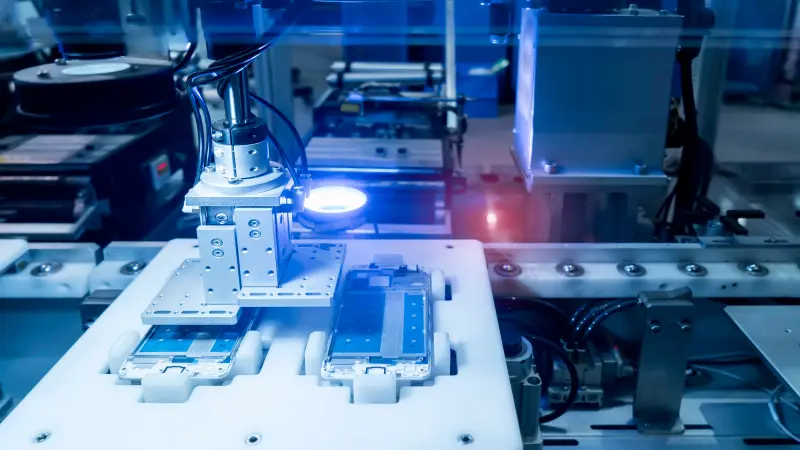

Production traceability

Achieve single-part traceability directly within the production process. Origify identifies every component by its natural material structure with no labels, no codes, and no added process steps.

This enables full part-level tracking, early detection of production issues, and avoids scrapping entire batches. The result: less downtime, faster decisions and significant cost savings.

Quality claims & returns

Enable fast and reliable root-cause analysis for returned or defective parts. Origify allows every component to be verified individually and traced back to its specific batch or production parameters, reducing unnecessary recalls and supporting quality audits.

Supply chain traceability

Create transparency and trust across multi-tier supplier networks. With Origify, every component carries its own secure material signature, enabling end-to-end authentication and traceability across manufacturing and logistics to support your product passport initiatives.

Challenges

- ☒ Limited traceability at the component level

- ☒ Risk of counterfeiting & gray market

- ☒ High control costs & time loss

- ☒ Lack of transparency in production and supply chain

Solution

- ☑ Digital traceability for every part

- ☑ Invisible product authentication

- ☑ Real-time smartphone authentication

- ☑ Complete digital identity