Origify Technology: Innovation for Your Organization

Product authentication & traceability for your digital identity

Even if two products appear identical to the human eye, their surfaces are fundamentally unique. Each material carries its own microstructure, formed naturally during production. Even items produced on the same machine, on the same day, show microscopic variations that make them scientifically distinguishable. In a world where counterfeit products threaten brands, supply chains, and consumers, Origify's material-based technology provides proof of authenticity directly within the product itself. By turning these natural material signatures into verifiable identifiers, Origify enables secure product authentication, complete traceability, and supports you in meeting the digital product passport requirements.

How it works

Origify identifies products by their natural microstructures. Every surface carries a unique pattern that we extract from a simple camera image. The analysis runs within seconds and requires no labels, markers, or added materials. Our technology works across a wide range of materials: metals, plastics, ceramics, composites, leather, and coated surfaces. This makes Origify suitable for industries where secure identification is critical: luxury, high security, automotive, industrial manufacturing, medtech, consumer goods, logistics, and the circular economy. Whether for components or finished products, verification stays robust, scalable, and tamper-proof.

Step 1: Registration

Each product is captured once using a camera device or in the production line. The material surface is analyzed, and its unique ID is securely stored in the cloud.

Step 2: Verfication

Users scan the product with the Origify App or a verification device and receive instant feedback on authenticity.

Step 3: Collect data

Brands gain real-time insights. From process and quality monitoring to supply chain transparency and counterfeit detection in consumer markets, Origify delivers actionable data for every stage of the product’s lifecycle.

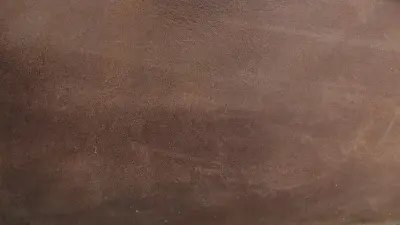

The principle of Origify

Look at these two leather samples, captured from the same position under identical conditions. The microstructure on the left differs from the one on the right. Origify recognizes and translates these natural surface variations into a unique digital ID that can be verified anytime, anywhere.

Origify in numbers

-

Our Origify surface based technology delivers up to 33% better wear-and-tear resistance than conventional methods. -

From capturing the photo to creating the cloud ID and having it ready to use, the complete product registration takes under 0.8 seconds.

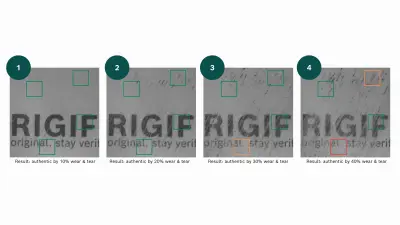

Wear and tear

Origify identifies products using multiple Regions of Interest across the surface. If one area is scratched, worn, or partially destroyed, the system relies on the remaining regions. Even with substantial abrasion, the natural microstructure provides enough signal to verify the original part, and we always rely on the real surface, not any artificial AI-based prediction or reconstruction. Our internal tests show reliable identification even with up to 40% surface wear, outperforming marker-based methods such as DMC or QR codes. In our lab, we’ve pushed parts through harsh, destructive scenarios, and the result is consistent: Origify remains stable, accurate, and trustworthy even under heavy real-world use.